Forklift safety cages are a crucial part of any warehouse or distribution centre. Without them, there would be no way to protect workers from potentially deadly machinery. There’s a lot more to forklift safety cages than meets the eye, though, and there are some essential things you should know before making a purchase decision. In this guide, we’ll cover all about what safety cages are used for, best practices for safe use, and how to choose a good product.

What Is a Forklift Safety Cage?

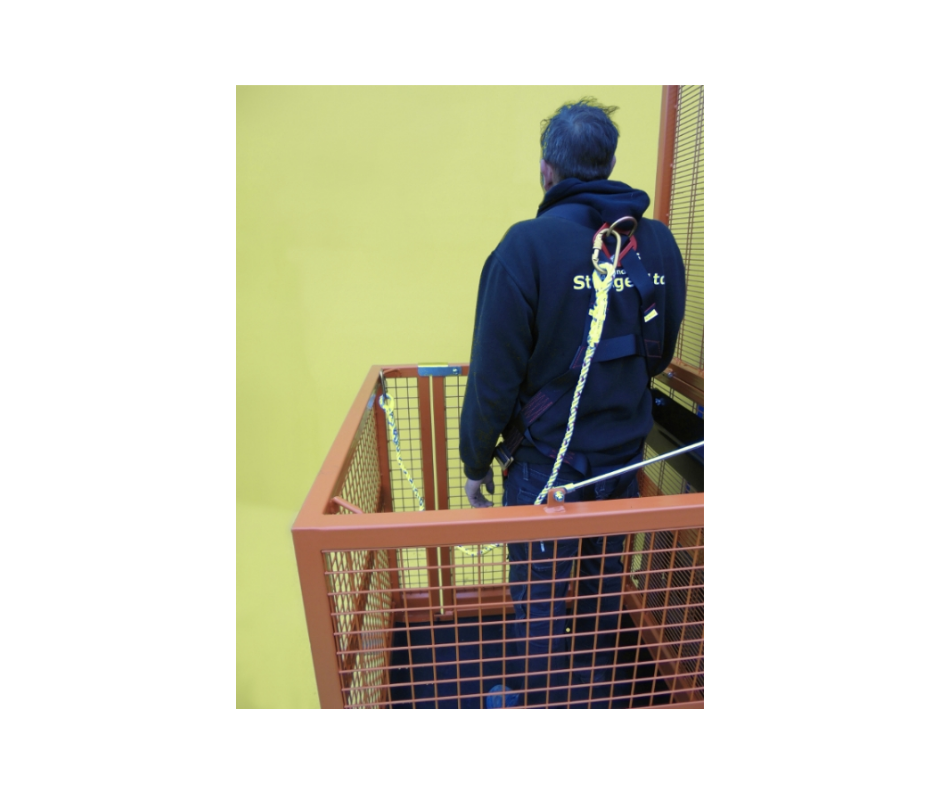

A forklift safety cage is a protective barrier used to lift a warehouse worker or workers high up into the air on top of a forklift. These cages are crucial because warehouse forklifts can easily reach heights of up to 15 feet, so there’s no better way than this for workers to access high shelves or other hard-to-reach places. These safety cages are typically made from steel tubing, wire mesh panels and/or solid sheet metal. Some cages incorporate side walls to further protect workers from flying debris should there be an accident.

Are Forklift Safety Cages That Important?

Yes, absolutely. Forklift accidents are incredibly dangerous and can lead to fatalities, permanent injuries, lost workdays and high turnover rates for businesses. Without access cages, these types of forklift accidents would happen far more often than they already do, so it’s crucial for warehouse managers to take all necessary precautions when operating their fleets. An investment in good quality protection is money well spent.

Best Practices For Safe Use

Safety is important when dealing with any machinery, but it’s especially crucial when working around large industrial forklifts. That’s why it’s so important for workers to adhere to these best practices when using access cages:

1) Always wear proper safety gear, including a hardhat, gloves and steel-toed boots

2) Get the necessary training before being allowed to work around machinery or equipment

3) Ensure no one walks underneath the cage while the lift is elevated.

4) Stay in communication with the forklift driver at all times and do not distract them.

How To Choose The Best Cage

Many industrial safety cages are available, but some are better than others for specific applications. When choosing which type will work best for your specific needs, you should make sure to keep these factors in mind:

Safety – The cage must be able to withstand any potential accidents such as a collision or tip over.

Transportability – You may need to transport it into different rooms depending on where it’s needed. Make sure that they can be moved by hand if necessary.

Flexibility – Can the cage easily adjust its size to fit onto various equipment? If not, then there will likely be problems when using them with larger machinery.

What Next?

Forklift safety cages are among the best ways to protect workers from accidents when operating machinery in warehouses or distribution centres. Make sure you pick a good quality cage that meets all safety measures, can be moved easily between rooms and has flexible sizing options depending on your needs. Visit our online store to browse our full line of safety cages for all your forklift needs.